Tesla vehicles are renowned for their stylish design and rigorous engineering, maintained through expert knowledge of specialized factory repair methods. These techniques, involving precise alignment and structural integrity checks, address misalignments from minor dents to significant crashes. Using advanced tools, high-precision measurement equipment, OEM parts, and CAD technology, Tesla technicians ensure seamless integration with the car's iconic design, preserving its longevity and value.

“Uncover the intricate world of Tesla factory repair methods, where precision and innovation converge. This comprehensive guide explores the art of OEM panel fitment and alignment, crucial for maintaining Tesla vehicle quality. Delve into the process, from initial assessment to final adjustment, to understand its significance in the brand’s reputation for excellence. Common challenges are addressed, offering valuable insights and strategies for effective mitigation, ensuring optimal results in Tesla factory repair.”

- Understanding Tesla Factory Repair Methods for Optimal Panel Fitment

- The Process of OEM Panel Alignment and its Significance in Tesla Vehicle Quality

- Common Challenges in Tesla Factory Repair and Effective Mitigation Strategies

Understanding Tesla Factory Repair Methods for Optimal Panel Fitment

Tesla vehicles are renowned for their sleek design and precision engineering, and maintaining optimal panel fitment is crucial to preserving this aesthetic. Understanding Tesla factory repair methods is essential for achieving precise alignment and seamless originality. These techniques are meticulously crafted to ensure that every component, from the car body repair to fender repair and auto frame repair, aligns perfectly with the vehicle’s iconic design.

By employing these specialized methods, Tesla technicians can expertly address any panel misalignment or damage, be it a minor dent or a significant crash. The process involves advanced tools and a deep knowledge of the vehicle’s structural integrity. This dedication to factory-level repair standards guarantees that the final result is not just a fix but a seamless integration, preserving the car’s original look and ensuring its longevity on the road.

The Process of OEM Panel Alignment and its Significance in Tesla Vehicle Quality

The process of OEM (Original Equipment Manufacturer) panel alignment is a critical step in ensuring the superior quality and precision that Tesla vehicles are known for. It involves meticulously adjusting and aligning the various panels and components of the car body to meet stringent factory specifications. This meticulous process begins with carefully removing the affected panels, often requiring specialized tools and techniques, such as Tesla-specific lifts and alignment equipment. Once removed, skilled technicians inspect each panel for any defects or misalignments, using advanced measurement tools to ensure precision down to the smallest fraction of a millimeter.

Proper OEM panel fitment and alignment are paramount for several reasons. Firstly, it guarantees a seamless, gap-free finish across the vehicle’s exterior, enhancing its overall aesthetic appeal. Secondly, precise alignment ensures structural integrity, crucial for safety and durability over the car’s lifecycle. Furthermore, achieving factory-level alignment during repairs can prevent future issues like panel warping or misalignment, ultimately contributing to better retention of vehicle value. This meticulous Tesla factory repair method, often referred to as auto body repair, is a testament to the company’s commitment to delivering high-quality, reliable vehicles that meet their stringent standards.

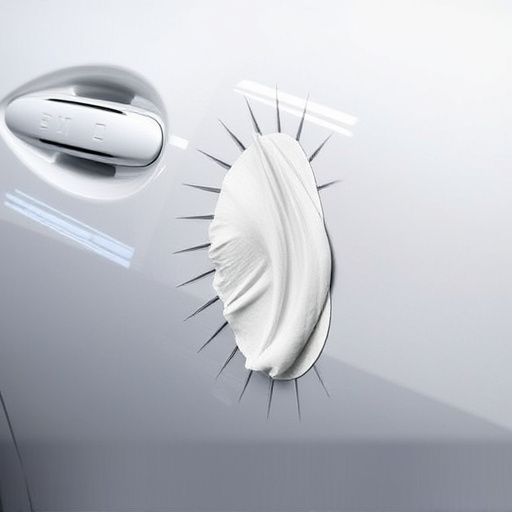

Common Challenges in Tesla Factory Repair and Effective Mitigation Strategies

Tesla factory repairs present unique challenges due to the vehicle’s advanced technology and precision manufacturing. One common difficulty lies in achieving precise panel fitment and alignment, especially when repairing damage incurred during production or transportation. The tight tolerances required for Tesla’s sleek and modern designs can make traditional repair methods less effective. For instance, misaligned panels or poorly fitted components may compromise the vehicle’s structural integrity and aesthetic appeal.

To mitigate these issues, a combination of specialized tools and advanced techniques is employed. Effective strategies include utilizing high-precision measurement equipment to ensure accurate repairs, employing original equipment manufacturer (OEM) replacement parts to maintain quality, and training technicians in the latest repair methods specific to Tesla vehicles. Auto dent repair experts also leverage computer-aided design (CAD) technology to create precise repair templates, ensuring that car restoration processes are both efficient and effective, ultimately resulting in flawless car dent repair outcomes.

Tesla’s commitment to precision manufacturing is evident through its innovative factory repair methods, ensuring optimal panel fitment and alignment. By understanding these techniques and addressing common challenges, we can maintain the superior quality expected of Tesla vehicles. Utilizing OEM parts and specialized equipment, along with effective mitigation strategies, facilitates precise repairs, preserving both the aesthetic integrity and structural soundness of Tesla’s iconic designs.