Tesla employs advanced materials and specialized techniques for factory repair, preserving vehicle aesthetics and performance. This includes precision cutting, spot welding, and expert paint matching to seamlessly blend with original finishes. Corrosion prevention is crucial, utilizing zinc coating, electrostatic painting, and sandblasting to safeguard against rust in electric vehicles. Modern innovations like automated robotic systems ensure precise repairs and maintain Tesla's iconic brand standards for top-tier aesthetic restoration and long-term protection.

Tesla vehicles are renowned for their cutting-edge technology, but like any car, they require maintenance. This article delves into the world of Tesla factory repairs, offering a comprehensive overview of the processes and techniques employed by professionals. From understanding the unique challenges of these repairs to exploring advanced corrosion prevention methods, we uncover best practices that ensure longevity. Learn how modern solutions are revolutionizing Tesla factory repair methods, keeping your electric vehicle in peak condition.

- Understanding Tesla Factory Repairs: An Overview

- Corrosion Prevention Techniques for Longevity

- Best Practices and Modern Solutions for Factory-Level Repairs

Understanding Tesla Factory Repairs: An Overview

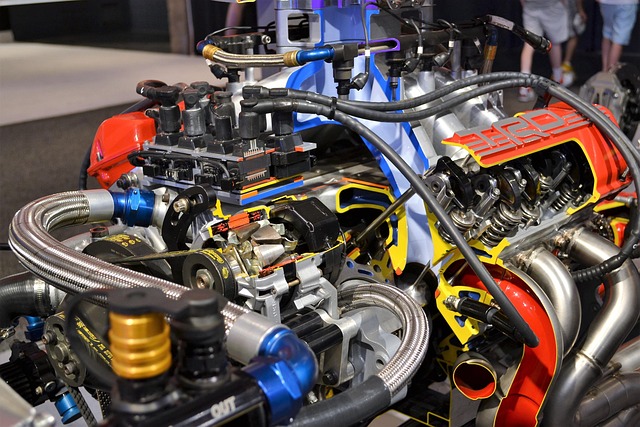

Tesla factory repairs encompass a comprehensive range of processes designed to restore vehicles to their original condition, ensuring top-notch quality and safety standards. These repairs differ from regular auto body repair or car collision repair in several key ways. For instance, Tesla’s manufacturing process includes advanced materials and sophisticated assembly techniques that demand specialized knowledge and equipment during the repair process.

Whether addressing minor dents or significant structural damage, Tesla factory repair methods prioritize preserving the vehicle’s original aesthetics and performance. This involves meticulous procedures such as precision cutting, spot welding, and expert paint matching to blend seamlessly with the car’s existing finish. By focusing on both functionality and visual perfection, these repairs not only enhance the car’s longevity but also uphold the brand’s reputation for innovative design and engineering excellence in vehicle dent repair and beyond.

Corrosion Prevention Techniques for Longevity

In the realm of Tesla factory repair methods, corrosion prevention stands as a cornerstone for longevity and optimal performance. Auto repair services that specialize in electric vehicles (EVs) like Tesla employ advanced techniques to safeguard against rust and decay, which are particularly significant challenges due to the unique materials and designs used in these cutting-edge cars. By integrating robust corrosion prevention steps into their processes, top-tier automotive body shops ensure that restored Teslas not only match their original aesthetic but also maintain peak functionality for years to come.

This involves a multi-faceted approach, including surface treatments like zinc coating and electrostatic painting, which create an additional barrier against moisture intrusion—a key contributor to corrosion. Additionally, these shops meticulously prepare the car’s body before applying new paint, using sandblasting or media blasting techniques to remove any traces of old, damaged finish, ensuring a clean slate for fresh, protective coatings. Such meticulous attention to detail not only restores the car’s exterior but also prevents future corrosion issues, enhancing the overall value and reliability of Tesla vehicles in the long run, whether handled by a specialized car body shop or as part of factory repair methods.

Best Practices and Modern Solutions for Factory-Level Repairs

In the realm of Tesla factory repair methods, modern solutions have revolutionized the way vehicle damage is addressed. Best practices now incorporate cutting-edge technologies and advanced materials to ensure precision and longevity in auto dent repair and car scratch repair processes. For instance, automated robotic systems are employed for consistent and accurate repairs, minimizing human error often associated with manual methods.

Additionally, corrosion prevention steps have become integral to factory-level repairs, considering the sensitive nature of Tesla’s electric vehicle components. Modern solutions involve advanced rust inhibitors and protective coatings, ensuring that vehicle collision repair processes not only restore aesthetics but also safeguard against future corrosion issues. These innovative practices reflect Tesla’s commitment to delivering top-tier repairs that meet the high standards set by their iconic brand.

Tesla factory repair methods prioritize longevity and quality through advanced corrosion prevention techniques and best practices. By implementing these strategies, repairs not only match the original standards but also ensure the vehicle’s structural integrity for years to come. Understanding these methods is key to maintaining Tesla vehicles, addressing potential issues early, and appreciating the brand’s commitment to excellence in every aspect of production and aftercare.